A Look at Material Handling and Assembly Lines: Exploring Conveyor Types and Their Benefits

Streamlining material handling processes is a cornerstone of modern manufacturing and production. Assembly lines and conveyor systems ensure the efficient flow of materials, components, and finished products throughout a facility. For businesses seeking tailored solutions, SPG Conveyor Systems provides expert design, delivery, installation, and support for conveyor belt systems, components, and sortation equipment. In this guide, we explore material handling and assembly lines, detailing the types of conveyors available and their key applications.

Understanding Material Handling

Material handling involves the movement, storage, and control of materials across various stages of production, distribution, and disposal. Effective material handling improves flow, reduces waste, and enhances workplace safety. The right conveyor system is essential for maintaining the productivity and precision of assembly lines.

SPG Conveyor Systems offers custom solutions tailored to meet the demands of diverse industries, ensuring optimal performance in manufacturing and distribution environments.

Conveyor Systems: Types and Applications

Selecting the ideal conveyor system depends on your operational requirements. Below, we outline some common conveyor types and their practical applications:

1. Belt Conveyors

One of the most adaptable conveyor systems, belt conveyors efficiently transport materials ranging from lightweight goods to heavier products.

- Standard Belt Conveyors

- Stainless Steel Belt Conveyors

- Extra Wide Belt Conveyors

- Mezzanine Belt Conveyors

- Swan Neck Belt Conveyors

- Bespoke Conveyors

Applications: Suitable for carrying packaged items, bulk materials, or heavy components.

Customization: SPG provides bespoke designs to address specific production challenges, offering durability and reliability.

2. Pneumatic Conveyors

Pneumatic conveyors rely on air pressure to move materials through enclosed systems, making them an excellent choice for bulk materials and fine powders.

Applications: Perfect for industries such as food processing, pharmaceuticals, and chemical production.

Advantages: Hygienic, dust-free operation, ideal for maintaining clean production environments.

3. Sortation Conveyors

Sortation systems are designed to organize, separate, and direct materials to their appropriate destinations. These are invaluable for high-volume facilities such as warehouses and distribution centers.

Applications: Commonly used for sorting packages, parcels, and products in e-commerce and logistics.

Technology: SPG integrates advanced sortation solutions that work seamlessly with automated production lines.

4. Modular Belt Conveyors

With interlocking plastic belts, modular belt conveyors offer durability and adaptability for specialized applications.

Applications: Widely used in the food and beverage industries, especially for environments requiring frequent cleaning.

Customization: Easily configured to handle varied product types and sizes.

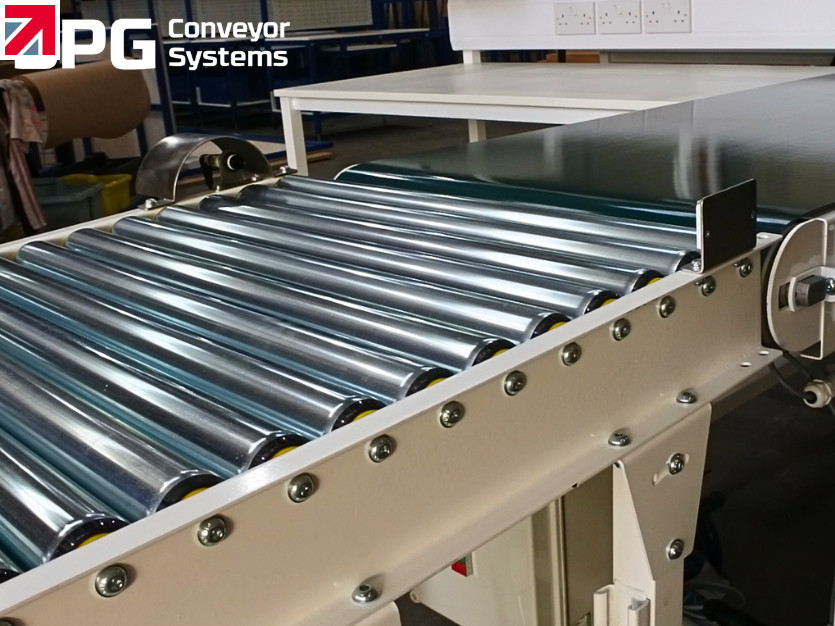

5. Roller Conveyors

Roller conveyors offer a cost-effective way to transport heavy loads and can be powered or gravity-driven, depending on operational needs.

Applications: Often utilized in assembly operations, warehouses, and packaging lines.

Customization: Flexible designs to suit specific spatial and logistical requirements.

6. Rotary Tables

Rotary tables are designed to hold, accumulate, or transfer products between conveyor lines, serving as a buffer in assembly or packaging processes.

Applications: Ideal for organizing and transitioning materials in production workflows.

Essential Conveyor Components and Their Functions

An efficient conveyor system relies on quality components. Each part plays a crucial role in ensuring seamless operation. Here are some common components and their functions:

Belts: Carry materials or goods between points. Available in rubber, plastic, or metal varieties.

Rollers: Support and enable belt movement. Suitable for both powered and gravity-fed systems.

Pulleys: Drive the belt and ensure proper tension. Essential for maintaining efficiency.

Motors and Drives: Provide consistent, controlled movement for automated processes.

Frames and Supports: Offer structural stability and are customizable for specific layouts.

Idlers: Prevent belt sagging and misalignment in longer systems.

Control Systems: Automate conveyor operations, ensuring precision in speed, direction, and integration with robotic systems.

Why Choose Bespoke Conveyor Systems?

Tailored conveyor solutions bring several benefits to manufacturing and production facilities. SPG Conveyor Systems specializes in creating custom systems that address industry-specific challenges, offering:

Improved Efficiency: Enhanced speed and accuracy in handling materials.

Long-Term Reliability: Systems designed for durability and minimal downtime.

Adaptable Designs: Modular layouts to meet evolving operational needs.

End-to-End Support: From initial consultation to final installation, SPG ensures smooth project execution.

What Sets SPG Conveyor Systems Apart?

As a leading UK conveyor manufacturer, SPG Conveyor Systems provides top solutions for material handling and assembly line optimization. With a commitment to innovation and quality, SPG delivers custom conveyor belt systems, components, and sortation equipment to clients across multiple sectors.

Final Thoughts

Efficient material handling is vital to the success of modern manufacturing. By choosing the right conveyor system—whether it’s a belt conveyor, pneumatic conveyor, or sortation system—you can enhance productivity, reduce waste, and optimize your operations. SPG Conveyor Systems provides the expertise and tailored solutions needed to meet your unique challenges.

📧 Contact us today: sales@spaceguard.co.uk

📞 Call us: 01482 363445

Explore our websites for more tailored solutions:

🌐 SpaceGuard.co.uk – Comprehensive workplace equipment

🌐 PackingTables.co.uk – Packing tables and benches

🌐 ConveyorSystems.co.uk – Conveyor solutions

🌐 CuttingTable.co.uk – Specialist cutting tables

Let SPG Conveyor Systems help you take your material handling and assembly operations to the next level!

Find out more about Spaceguard Ltd on their member profile page here

Member-created content 2 months ago | From members